Passengers value punctuality in transportation. Moreover, they expect the transportation system to be available at all times. The punctuality, reliability and availability of any mode of transportation is therefore very important. These characteristics determine the degree of delays, accidents and cancelled trips present in the system. In other words, they comprise the operational performance. By taking reliability and availability into account early in the Hyperloop development, the operational performance can be improved significantly. A collaboration between Movares and Delft Hyperloop was established to perform a RAM (reliability, availability and maintainability) analysis of the Hyperloop system.

The Hyperloop presents itself as an alternative to short-to-medium-haul flights. Therefore, the availability and reliability targets of aviation can be used as a guideline for those of the Hyperloop. Moreover, it is important to define the term non-availability. The Hyperloop system is non-available when, due to technical failures or corrective maintenance, no passengers or cargo can be transported. Using this definition and data from commercial airlines as reference (Cirium, 2019), the following targets are set:

The target for completed pod movements of the European Hyperloop network is set at 99%. This means that one out of every hundred pods will not complete its journey. The target for on-time pod arrivals of the European Hyperloop system is set at 90%. An arrival is considered on-time within 5 minutes of the scheduled station arrival time. This means that one out of every 10 pods will be delayed by more than 5 minutes.

Reliability analysis

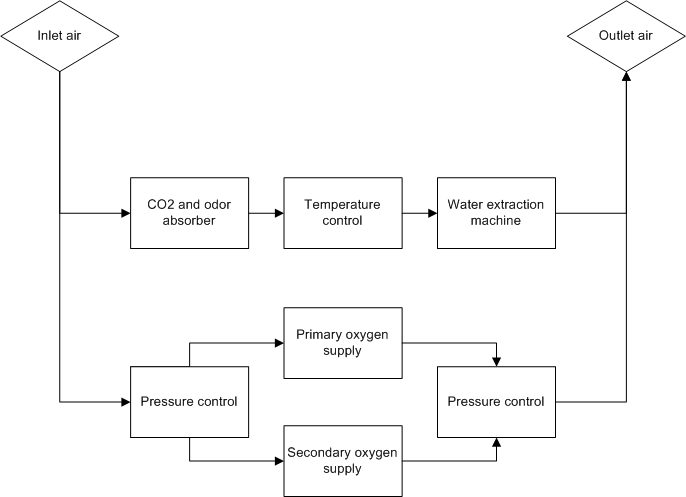

Now that the targets have been defined, the reliability of the Hyperloop system can be analysed. Several subsystems of the Hyperloop were reviewed in the assessment. In this article the environmental control system (ECS) is used as an example. The primary function of this subsystem is to maintain a safe environment inside the Hyperloop pods by controlling pressure, temperature and oxygen levels. Figure 1 gives an overview of the different components of the ECS. Air enters the ECS and the CO2 levels, temperature, humidity, oxygen levels and pressure get adjusted to optimal levels before returning to the pod.

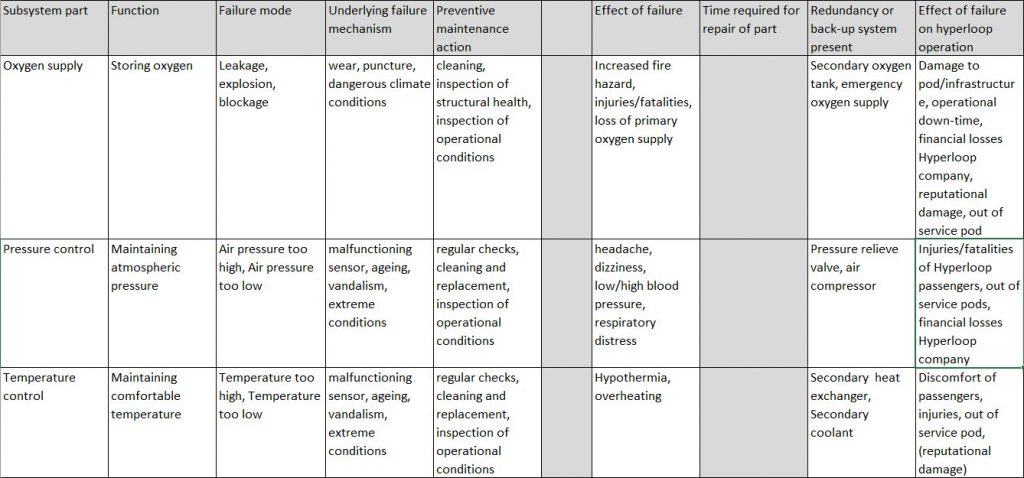

The system has been described and the next step is to answer several questions regarding each component. To get a better understanding of the reliability of the components of each subsystem and system level, the following questions can be posed:

- What is the function of the component?

- What are the failure modes of the component?

- What is the effect of failure and how can failure be prevented?

The answers to these questions for each subsystem are compiled in a reliability analysis. Figure 2 shows a part of the reliability analysis for the ECS.

The components of each subsystem have been identified and the corresponding failure modes have been described. A good method to visualize the different failure modes in subsystem is by creating a fault tree (see the PDF below). A fault tree is a structured logic diagram in which certain specific causes lead to one specified event of interest (Lee et al., 1985). In this case the event of interest is a hazardous pod environment.

The fault tree explains how specific causes, called basic events, such as failure of the door mechanism or water extraction machine can cause a dangerous environment inside the Hyperloop pod. The rate of occurrence of each basic event gets determined and then, using statistics, the probability of the event of interest can be calculated.

RAM Management

By using a reliability analysis, the chance of failure of subsystems in the Hyperloop pod and infrastructure can be determined. These analyses are important during the current phase of the Hyperloop development as they create a more robust and safe Hyperloop design. However, improving the Hyperloop performance does not stop after the design phase. Even when the Hyperloop is operational reliability and availability can be improved. RAM management is a method to accomplish this and includes tasks such as:

- System monitoring and preventive maintenance;

- Application of good quality management practices;

- Provision of back-up systems so that a single failure does not result in loss of function.

Conclusion

The Hyperloop aims to offer the best possible service to its passengers. Therefore, accidents, delays and cancelled trips should be minimised. An extensive reliability analysis during the design phase can be a tool to achieve this. Moreover, RAM management is a method to ensure the reliability and availability of the system during operations. Further research into the reliability of the Hyperloop can be done by performing a quantitative fault tree analysis and reliability analyses for all the Hyperloop subsystems. All this to ensure that the Hyperloop will not only be a fast, comfortable and sustainable but also a reliable mode of transportation.

This reliability and RAM analysis was done in collaboration with Movares. Movares is a Dutch engineering firm specialized in mobility and infrastructure. The collaboration was kicked-off with a workshop on reliability of transportation and RAM(S) analysis. By bundling the expertise of Movares with the Hyperloop knowledge of Delft Hyperloop, a reliability and fault tree analysis of the Hyperloop system was created. We look back at a very pleasant and fruitful collaboration!

References

- Cirium. (2019). Cirium on-time performance review 2019.

- Lee, W. S., Grosh, D. L., Tillman, F. A., & Lie, C. H. (1985). Fault Tree Analysis, Methods, and Applications ߝ A Review. IEEE transactions on reliability, 34(3), 194-203.

0 Comments